The definitive version for the implementation of this standard is the edition bearing the most recent date of issue obtainable from beuth verlag gmbh burggrafenstraße 6 10787 berlin germany.

M24 eye bolt lifting capacity.

Always apply load to eye bolt in the plane of the eye.

Standard forged eye bolts should not be used with angular lifts.

Eye bolts eyebolts and eye nuts eyenuts are also commonly known in the lifting industry as lifting eyes.

Crosby 277 forged shoulder nut eye bolts crosby 277 forged shoulder nut eye bolts crosby 291 forged regular nut eye bolts crosby 291 forged regular nut eye bolts rivet.

Load limits are based on a safety factor of 5 to 1.

Available in a wide range of metric and imperial sizes aswell as high tensile steel or stainless steel.

Never machine grind or cut eye bolt.

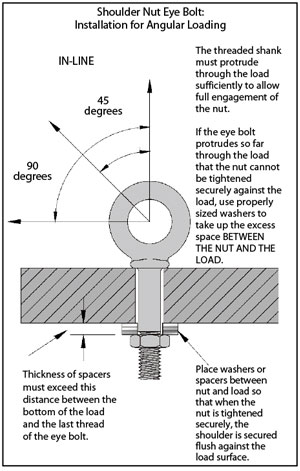

If an angular lift is required a properly seated shoulder pattern machinery eye bolt must be used.

For angular lifts adjust working load as shown above.

Always be sure threads on shank and receiving holes are clean.

Never use regular nut eye bolts for angular lifts.

The larger internal eye diameter offers a versatile alternative to standard grade 4 eyebolts.

Crosby m 279 metric forged shoulder type machinery eye bolts crosby m 279 metric forged shoulder type machinery eye bolts nut.

Variety of shapes and designs such as din standard eye bolts collar bs4278 standard eyebolts long shank dynamo type and eyebolts with built in oval links.

Lifting capacity per eye bolt with bolt fitted at sides of load 45 reproduced by permission of din deutsches institut für normung e.

Never use eye bolt if eye or shank is bent or elongated.

Din 525 weld studs with hexagon nuts.

Always use shoulder nut eye bolts for angular lifts.

Never exceed work load limits specified in tables 1 2.

Always tighten nuts securely against the load.

Never use regular nut eye bolts for angular lifts.

Din 529 a anchor bolts stone bolt din 529 b anchor bolts stone bolt.

Not intended for use where the load is perpendicular to the thread.

Grade 8 eye bolts offer up to 4 times higher lifting capacity in certain applications.

Working load limits for eye bolts are based on a straight vertical lift in a gradually increasing manner.

Never use eye bolt that shows signs of wear or damage.

Never exceed working load limits.

This is because in these instances the bolt could unscrew and move or it could be twisted and break.